What is Advanced Machine Vision?

Advanced Machine Vision refers to the use of AI-powered technologies that enable machines to see and interpret visual data. Unlike traditional machine vision, which relied on pre-set rules and limited processing capabilities, advanced machine vision combines sophisticated algorithms, high-resolution cameras, and image-processing software. This powerful combination allows systems to analyze and make decisions based on visual inputs autonomously, without human intervention.

With the support of AI and deep learning, advanced machine vision now plays a vital role in various industries, from manufacturing and healthcare to autonomous vehicles and retail. These advancements are making a significant impact by streamlining processes, reducing errors, and enhancing precision.

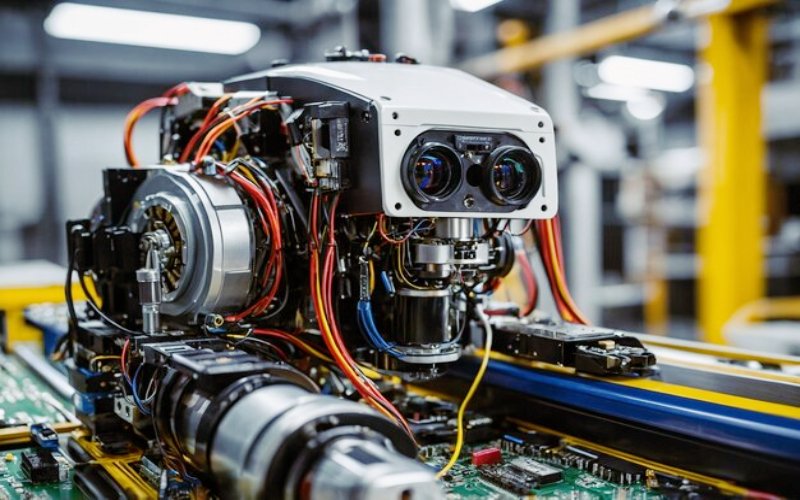

Key Components of Advanced Machine Vision

The primary components of advanced machine vision systems include:

Cameras and Sensors

High-resolution cameras capture images or video footage with clarity and detail. Paired with sensors, these components allow the machine vision system to gather visual data accurately in various lighting and environmental conditions.

Lighting Systems

Effective lighting ensures that images are consistent and clear for analysis. Many systems use specialized lighting setups to reduce shadows and enhance visibility, which is essential for high-precision tasks.

Processing Units and AI Chips

The processing unit is the “brain” of the machine vision system, using CPUs, GPUs, or AI chips to process visual data rapidly. These processing units allow the system to handle data-heavy tasks in real time, which is crucial for applications requiring immediate decision-making.

Image Processing and AI Software

Software algorithms enable advanced machine vision systems to interpret, analyze, and respond to visual data. These algorithms may include deep learning models capable of recognizing patterns, detecting objects, and making complex classifications.

Together, these components allow advanced machine vision systems to perform tasks with speed, accuracy, and adaptability.

How Advanced Machine Vision Works

The operation of advanced machine vision involves four main steps:

- Image Acquisition: Cameras capture the necessary visual data in real-time.

- Pre-processing: Algorithms enhance the image quality to prepare it for analysis.

- Feature Extraction: Key features are extracted, such as shapes, colors, or textures relevant to the task.

- Decision-Making: Based on the extracted features, the system makes decisions, takes actions, or provides insights.

By integrating these steps, advanced machine vision can carry out detailed analysis and autonomous actions, making it suitable for dynamic environments where precision is critical.

Applications of Advanced Machine Vision

Advanced machine vision has broad applications across multiple sectors, enhancing efficiency, accuracy, and safety. Some of the most notable applications include.

Manufacturing

In manufacturing, advanced machine vision systems inspect products for quality and detect defects, ensuring consistency across production lines. By automating these quality control processes, manufacturers can improve product quality, reduce waste, and enhance productivity.

Healthcare

Machine vision assists healthcare professionals by analyzing medical images, such as X-rays, MRIs, and CT scans. With advanced machine vision, anomalies can be detected faster, helping doctors make accurate diagnoses and improve patient outcomes.

Automotive

In the automotive industry, advanced machine vision is integral to autonomous vehicles. These systems can detect road obstacles, recognize traffic signals, and help vehicles stay within lane markings, making self-driving technology safer and more reliable.

Agriculture

In agriculture, machine vision aids in precision farming by identifying crop health, detecting pests, and optimizing resource use. This application of machine vision helps farmers make better decisions and increase crop yields.

Machine vision also contributes to advancements in sectors like logistics, retail, and security, where visual analysis plays a crucial role in operational success.

Benefits of Advanced Machine Vision

The benefits of advanced machine vision are numerous, transforming industries with improved accuracy, higher productivity, cost savings, and enhanced safety.

Improved Accuracy and Reduced Error Rates

Advanced machine vision systems can reduce human error by automating complex inspection processes, resulting in more consistent and precise outcomes. This capability is particularly valuable in industries like electronics, where minute defects can lead to significant product failures.

Increased Productivity

By automating repetitive tasks, advanced machine vision enables companies to increase production speed without sacrificing quality. The technology handles inspection, quality control, and monitoring tasks with unmatched speed, freeing up human workers for more critical roles.

Cost Savings

Implementing advanced machine vision technology may require an upfront investment, but the long-term cost savings are substantial. By reducing errors, minimizing waste, and decreasing the need for manual quality control, companies can significantly cut operational costs.

Enhanced Safety

In environments where safety is a concern, machine vision systems can identify potential hazards and prevent accidents. This feature is especially useful in industrial settings, where machine vision can monitor for unsafe conditions and alert personnel immediately.

Challenges and Limitations of Advanced Machine Vision

Despite its benefits, advanced machine vision faces several challenges:

High Initial Costs

Setting up advanced machine vision systems can be expensive due to the cost of high-quality cameras, AI models, and processing units. The initial investment may be a barrier for smaller companies.

Complexity and Technical Expertise

Developing and managing advanced machine vision systems require expertise in AI, image processing, and software engineering. Companies need skilled personnel to maintain and optimize these systems, which may add to operational costs.

Environmental Sensitivity

Advanced machine vision can be affected by environmental factors like lighting, temperature, and movement. Adjustments are often required to maintain accuracy in various conditions, which can complicate installation and use.

Data Privacy Concerns

Collecting visual data raises concerns about privacy, especially when used in public areas or sensitive environments. Companies must handle visual data responsibly and adhere to data privacy laws to prevent misuse.

The Role of AI in Advanced Machine Vision

Artificial intelligence (AI) has revolutionized machine vision by enabling systems to process data in real-time, learn from experiences, and improve over time. With AI, advanced machine vision systems can:

- Recognize and classify images with high accuracy.

- Adapt to new tasks and environments through machine learning.

- Continuously improve performance with exposure to more data.

AI-based vision systems can perform complex tasks such as facial recognition, object tracking, and quality assurance, making them invaluable in various industries.

Future Trends in Advanced Machine Vision Technology

The future of advanced machine vision is promising, with several key trends likely to shape its development:

Edge Computing

Edge computing allows data processing closer to the source, reducing latency. This capability is crucial for applications requiring real-time response, such as autonomous vehicles and industrial robotics.

3D Vision Systems

By integrating 3D vision, machine vision systems can measure depth, which is particularly useful for robotics and spatial analysis. This technology is paving the way for more advanced automation in sectors like manufacturing and logistics.

Multi-Spectral Imaging

Multi-spectral imaging expands the range of visible and invisible light captured, improving inspection accuracy. Applications range from industrial inspections to healthcare imaging, where detailed analysis is essential.

IoT Integration

As machine vision becomes part of the Internet of Things (IoT) ecosystem, it enables connected systems that gather, analyze, and act on visual data. This integration is creating more intelligent systems capable of monitoring and optimizing processes automatically.

Conclusion: The Impact of Advanced Machine Vision on Industry and Innovation

Advanced Machine Vision has the potential to reshape industries, enhance productivity, and drive innovation. By automating inspection, monitoring, and analysis tasks, machine vision reduces errors, increases efficiency, and enables new possibilities for automation. As technology advances, advanced machine vision will become an indispensable tool in various sectors, from manufacturing and healthcare to automotive and agriculture.

For businesses seeking precision, efficiency, and enhanced safety, investing in advanced machine vision technology could be a strategic step toward a smarter and more automated future.

Also visit on techitl.com.