Understanding AI-Enhanced Industrial Automation

AI-Enhanced Industrial Automation is reshaping industries by making machines smarter, processes more adaptable, and operations more efficient. Industrial automation, which has traditionally focused on improving efficiency, reducing costs, and ensuring precision, now integrates artificial intelligence (AI) to reach unprecedented levels of sophistication.

In essence, AI-enhanced industrial automation combines technologies like machine learning, computer vision, and natural language processing to elevate traditional automation systems. Unlike conventional automation that relies on pre-programmed instructions, AI empowers systems to learn from data, adapt to changing conditions, and make real-time decisions.

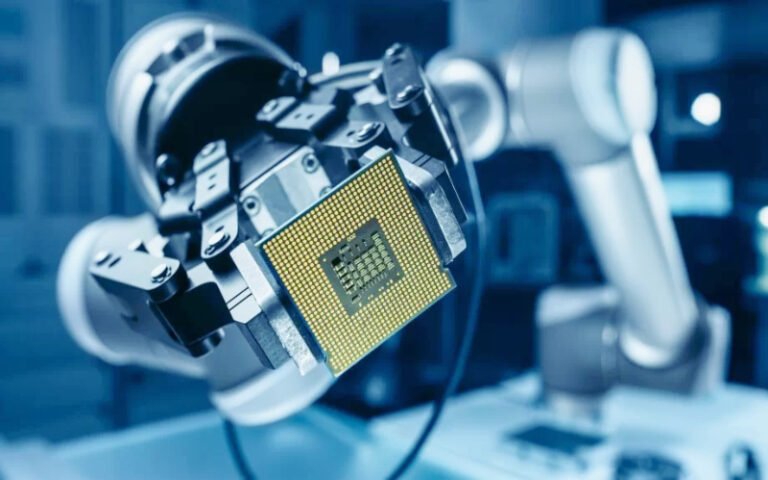

For instance, an AI-powered robotic arm in a factory can analyze sensor data, optimize its movements, detect anomalies, and predict maintenance needs without human intervention. This dynamic capability highlights why AI-enhanced industrial automation is revolutionizing industries.

Applications of AI-Enhanced Industrial Automation

Predictive Maintenance

Predictive maintenance is one of the most impactful applications of AI-enhanced industrial automation. By analyzing data from machinery sensors, AI algorithms can predict when equipment is likely to fail, minimizing unplanned downtime and reducing maintenance costs.

For example, AI-powered systems can monitor parameters like vibrations and temperature, flagging abnormalities early. This proactive approach ensures machines remain operational without costly disruptions.

Quality Control

AI-driven computer vision systems have transformed quality control processes. These systems identify product defects with exceptional accuracy and speed, surpassing human inspection capabilities.

In industries like automotive manufacturing, AI-enhanced industrial automation inspects paint jobs, welds, and component assemblies, ensuring high-quality standards. This improves customer satisfaction and reduces waste from faulty products.

Supply Chain Optimization

AI enhances supply chain efficiency by predicting demand, managing inventory, and improving logistics. Machine learning models analyze historical data and market trends to ensure resources are optimally utilized.

In warehouses, AI-powered robots handle inventory management and order fulfillment with unmatched precision. These advancements significantly reduce operational costs while improving delivery timelines.

Collaborative Robots (Cobots)

Collaborative robots, or cobots, are a prime example of AI-enhanced industrial automation. Cobots work alongside humans, leveraging AI to improve adaptability and safety.

On assembly lines, AI-driven cobots perform repetitive tasks, enabling human workers to focus on more complex activities. Cobots also detect and avoid collisions, ensuring workplace safety.

Benefits of AI-Enhanced Industrial Automation

Increased Efficiency

AI-powered systems operate around the clock without fatigue, delivering consistent performance. They process vast amounts of data quickly, identify bottlenecks, and optimize workflows, leading to enhanced productivity.

Cost Reduction

Automation reduces labor costs, and AI further cuts expenses by minimizing errors, reducing material waste, and optimizing energy consumption. Predictive maintenance also prevents costly machine breakdowns, saving time and money.

Improved Decision-Making

AI systems analyze real-time data to provide actionable insights. These insights help managers make informed decisions, whether it’s adjusting production schedules or reallocating resources efficiently.

Enhanced Safety

AI-driven automation reduces human involvement in hazardous environments, ensuring worker safety. From mining operations to chemical plants, AI systems monitor conditions and predict risks to prevent accidents.

Challenges in Adopting AI-Enhanced Industrial Automation

High Initial Costs

Implementing AI-powered automation systems requires substantial investment in hardware, software, and training. For small and medium-sized enterprises, these upfront costs can be a significant hurdle.

Skill Gap

AI-enhanced industrial automation demands a skilled workforce for development, deployment, and maintenance. Many organizations struggle to find talent with the necessary expertise.

Data Quality and Security

AI systems depend on high-quality data for accurate predictions and decisions. Poor data quality can lead to inefficiencies, while data security concerns pose risks of unauthorized access and breaches.

Resistance to Change

Employees and stakeholders may resist adopting AI-enhanced automation due to fears of job displacement or skepticism about its effectiveness. Clear communication and training programs are crucial to address these concerns.

The Future of AI-Enhanced Industrial Automation

Autonomous Systems on the Rise

As AI technologies advance and become more affordable, the adoption of autonomous systems is expected to accelerate. From self-driving forklifts to fully automated production lines, the potential applications are limitless.

Integration with IoT and Edge Computing

The integration of AI with the Internet of Things (IoT) and edge computing will enable real-time decision-making at data sources. This will enhance efficiency, reduce latency, and improve system reliability.

Advancing Sustainability Goals

AI-enhanced industrial automation will play a pivotal role in achieving sustainability. By optimizing energy consumption, reducing waste, and improving resource allocation, industries can significantly lower their environmental impact.

Conclusion: Embracing the Potential of AI-Enhanced Industrial Automation

AI-Enhanced Industrial Automation is more than just a technological trend; it is a transformative force driving the next wave of industrial innovation. Despite challenges such as high initial costs and skill gaps, the benefits—including increased efficiency, cost reduction, and improved decision-making—make it an indispensable part of modern manufacturing.

By embracing AI, industries can unlock new levels of adaptability and precision, securing a competitive edge in a rapidly evolving market. As technology advances, the possibilities for AI-enhanced industrial automation will only grow, cementing its place as a cornerstone of the future of manufacturing and beyond.

Also visit on techitl.com.